MetaTopo II: Development of a Data-Driven, Process-Oriented Geometry Optimization for Sand and Permanent Mold Aluminum Casting

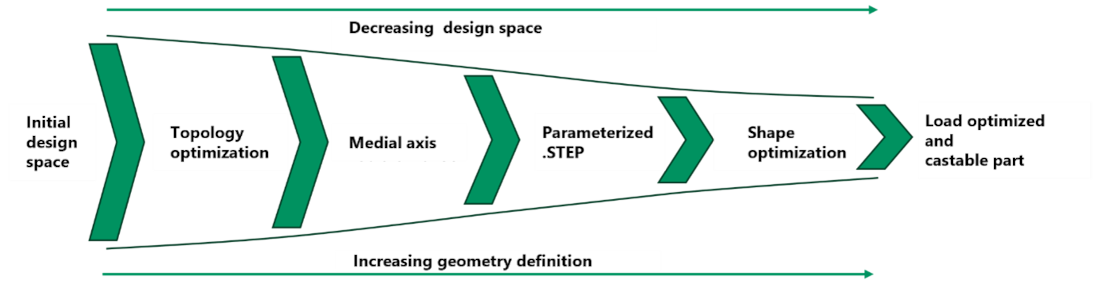

The extensive design freedom available in the design of cast components makes structural optimization methods particularly suited for developing components optimized according to load conditions. Currently, casting-specific requirements within structural optimization, if considered at all, are typically addressed using rudimentary manufacturing constraints. Examples of manufacturing constraints commonly applied in casting processes include draft angles, avoidance of undercuts, as well as extrusion or symmetry boundary conditions. An alternative approach is the integration of comprehensive casting simulations into the topology optimization (TO) process to incorporate detailed process knowledge. Both current methods, however, have limitations. Incorporating basic manufacturing constraints restricts the accurate representation of the actual casting process, whereas detailed casting simulations entail considerable computational effort. This research project aims to integrate process knowledge from gravity-driven casting processes into structural optimization through data-driven models characterized by low computational complexity, thus enabling their practical application in optimization loops. Using this method, it becomes feasible to generate load-optimal component structures while simultaneously considering casting requirements during the structural optimization process. Here, the design freedom is successively reduced as geometric definition progresses.

Funnel-shaped, integrated optimization workflow for the concurrent design of load- and manufacturing-compatible components within the current research project.

This approach significantly reduces development times and produces components closer to load-optimized configurations compared to traditional methods involving separate structural optimization and process design steps. The research extends the state-of-the-art by integrating solidification behavior into structural optimization, evaluating this behavior through geometric models that require significantly less computational effort than physical simulations based on numerically intensive partial differential equations. A substantial part of the effort involves transferring and reconstructing geometries across different software tools. Thus, this project will investigate methods to describe geometries using sub-volumes without requiring manual reconstruction.

Contact: Felix Hartwig, M.Sc.